Smart Industries

Inspiring Leap into the Grocery Business with RFID Technology

Smart Industries

Global company DENSO provides automotive technology as well as advanced mobility solutions. The firm that famously developed the QR code in 1994, provides automatic identification today, as well as serving automotive OEM’s, and RFID technology users. The company is headquartered in Japan, with offices worldwide.

To accommodate global demand for its products and services, the company utilizes thousands of IT assets at its facilities, that periodically must be manually audited. The manual process of identifying and counting thousands of high value assets was both time consuming and labor intensive.

In fact, audits often required inventory managers to identify serial numbers printed on each asset, or asset label, and then compare those numbers with the inventory list in their management system. Such serial numbers can be small, difficult to read, and may require an asset to be moved, turned or rotated to simply locate that number. Accomplishing such a task with thousands of assets at numerous sites often required weekend work and could not be conducted frequently.

What the company needed was a way to automatically capture the location of its inventory of laptops, PC’s, printers among its other electronic devices in an accuracy and efficient manner.

DENSO had some of its own tools to help build a solution. The company has the benefit of its Products and Services sector which delivers technical savvy as well as products that enable unique identification, including software, RFID readers and QR codes. So, Denso then went to Confidex to leverage RFID tags that store and transmit unique asset data to make the inventory audit system accurate, fast and seamless.

Confidex provided DENSO with the exceptional performance needed in an indoor IT asset tracking environment, as well as personalized printing and encoding to suit DENSO’s needs. The system is completely compatible with the DENSO SP1 handheld reader.

DENSO and Confidex started developing the solution in 2019. The goal was to build an IT asset tracking solution that leveraged a database designed by DENSO, while using RFID tag field data from Confidex tags. Confidex provides its own UHF RFID labels as well as printing and encoding services through service bureau Atlas RFID.

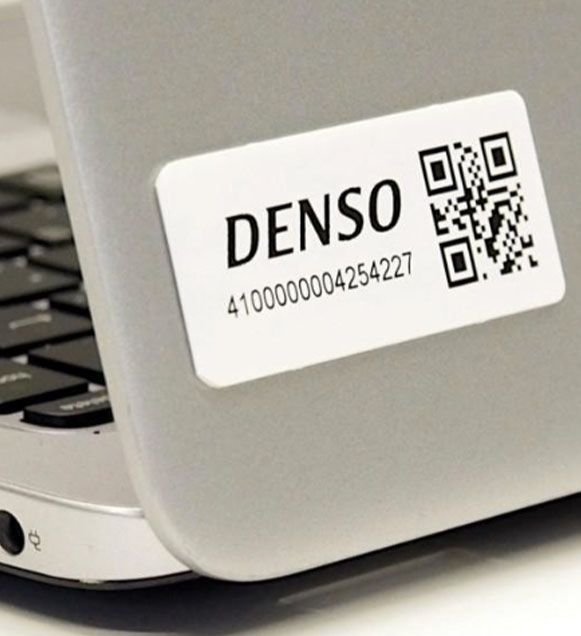

For this application, DENSO selected the Confidex Silverline Blade tags, the industry-leading IP68 classified label for on-metal applications. The UHF RFID tag offers several advantages. It is easy to print and encode making the process of tagging existing and new assets fast and simple. Its small footprint enables discrete labelling of even small electronics, while it offers a 4.5 meter read range on metal. The tag’s industrial grade adhesive ensures secure adhesion to each asset.

As the tags are encoded, each tag is also printed with a QR code linked to the tag RFID number in the database. As the tag is commissioned, users can seamlessly integrate the new labels into the ERP system by scanning the QR code and linking it to the RFID tag ID.

“Using RFID tags from Confidex along with our own high speed RFID scanners, DENSO has been dramatically reducing the time it takes to do our IIT asset audits,” says David E Williams, senior network analyst, DENSO products and services Americas Inc., “not to mention the stress on my back.“

The DENSO and Confidex development team then deployed the solution to take advantage of RFID tags for two purposes: to identify the asset, and to identify the location the asset is in, such as a room, office or storage area. Location tags are linked with a physical space in the DENSO’s ERP system, while asset tags are linked to the serial number and details of the IT equipment being tracked. The ERP system stores a record of the assets and their authorized locations.

As goods are received at the participating DENSO sites, the tags are attached to them – whether they are metal or non-metal assets. The development team also mounted the location tags on support poles in the warehouse as well as in key locations in offices such as over the doorjambs. Those conducting audits employ DENSO’s BHT 1281 handheld scanner to read the tags. The tags are completely compatible with the device and each tag can be read at a distance of about six feet.

Once an individual begins the audit process, he or she no longer need to search for serial numbers and write down inventory count details. Instead, when conducting an audit, users first read the location tag with their handheld device and then walk through that area, reading the tags of all assets within read range, and automatically creating a record of what was found during the audit.

The readers are recharged at a docking station where the read data is transferred to a computer and imported into the in-house asset tracking database. Users can then view any exceptions such as an item that may be missing or misplaced. The system enables use of the readers in “Geiger counter mode” as well as to seek a missing item. The reader leverages the Windows CE operating system.

Future implementations will employ SP1 handhelds with Bluetooth capabilities so that the data is automatically forwarded to the server.

DENSO has been piloting the technology at two of its sites: in Long Beach CA and Marietta GA, during which 2000 assets were tagged and tracked. Going forward Confidex’s RFID tags are being applied to new equipment as it is purchased at these sites, including printers and PC’s, laptops and handheld computers as well as other capital expenditures.

Based on the successful results of the pilot, the system is being expanded. The next installations will take place at five Indiana warehouse locations. Dozens more locations will be rolling out the technology in future years, expanding beyond warehouse storage and office environments to tracking high value IT assets in manufacturing plants.

Thus far, where the system has been deployed, DENSO has enjoyed a boost in inventory accuracy so that management can be confident they know what assets are onsite and accounted for. For the auditors themselves, the process of identifying each asset is easier and requires fewer manhours. In fact, accessing data about inventory counts now is just a matter of a few clicks.

The company has measured the results as well. While standard manual audits required about 64 hours, DENSO anticipates a reduction to between six and eight hours. The number could be reduced even further, if every asset was tagged with RFID. Another benefit for employees is the ergonomics, they report the system is user friendly and easy to operate.

DENSO says it found Confidex to be easy to work with and willing to take-on the extra effort to ensure the pilot personalization and customization that was needed. DENSO has found the Silverline Blade tags easy to apply, robust with strong adhesive, and effective reliable reads. Even when mounted inside an asset such as a laptop, the tags were being read consistently, DENSO found. And the additional visual personalization of the tags — in the form of QR codes — makes the process easier.

A strong partnership between the two companies ensured the development and piloting were successful. In fact, the partnership serves as a powerful combination to address tracking of assets or materials, says Joe Hoerl, Confidex EVP Smart Industries, Americas Business Unit. “Confidex’s understanding of complex RFID tagging scenarios, its deep engineering expertise, and collaborative approach with our partners is uniquely complimentary to the DENSO Products and Services’ RFID software and hardware offering.”

Together, the partners offer industry leading technology products and platforms to address a wide variety of needs at DENSO and other manufacturing facilities across the world. The solution goes fully live in 2021.

DENSO is one of the world’s largest automotive suppliers of technology and components found in almost all vehicles around the globe – Toyota, Honda, FCA, General Motors, Ford, Volvo Mercedes-Benz, to name a few.

DENSO Products and Services Americas, Inc. (DPAM) is an automotive components sales and distribution company supplying parts for original equipment service dealers and for the independent aftermarket service centers and retailers.